what is Pipeline Anticorrosion? Pipe Anti Corrosion Type and Process Flow

Description of pipeline anti corrosion

Pipeline anti corrosion is a measurement to slow down or prevent corrosion and deterioration of the pipeline under the influence of chemical or electrochemical action or the metabolic activities of microorganisms

What is pipeline corrosion phenomenon?

Corrosion can be understood as a chemical reaction of materials in the environment in which they are located. This reaction will cause the loss of pipeline materials and lead to failure of pipeline components or even the entire pipeline system. Whether the pipeline corrosion will spread, and the extent of the spread mainly depends on the corrosive force of the corrosive medium and the corrosion resistance of the existing pipeline materials. Temperature, concentration of corrosive medium and stress conditions will affect the degree of corrosion of the pipeline.

How many kinds of Anti-corrosion type?

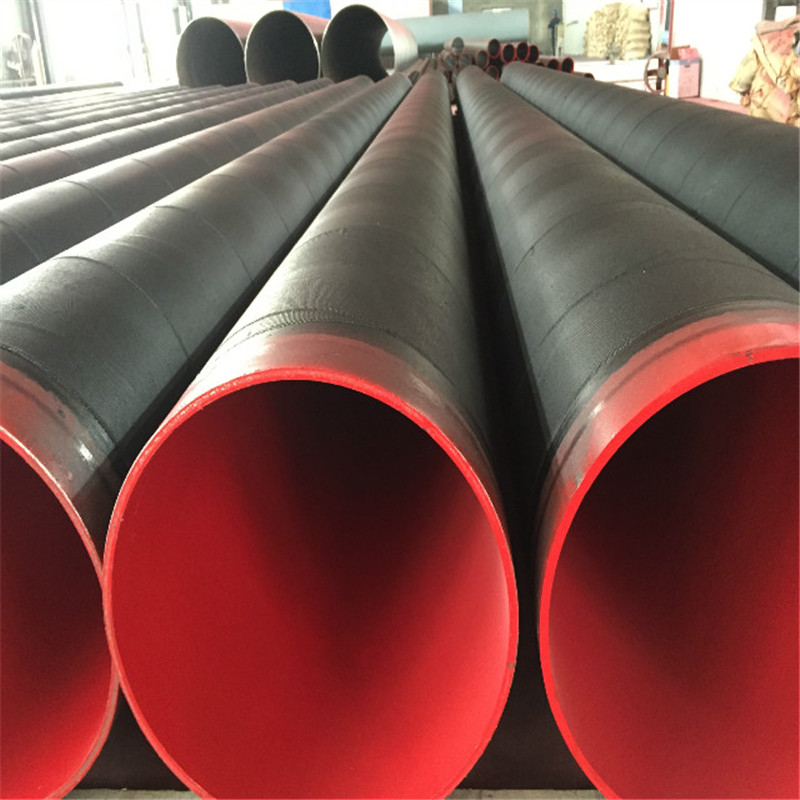

FUSION BOND EPOXY COATINGS

Fusion Bond Epoxy ,is short for FBE coating,using electrostatic spraying method, good fusion with pipe body in same anti corrosive materials, and strong adhesion, but epoxy powder has poor water resistance (high water absorption rate, up to 0.83%), this brings difficulties on the cathode protection design . On-site appliances are in high demanding, difficult to operate, and difficult to control quality. These are the disadvantages .

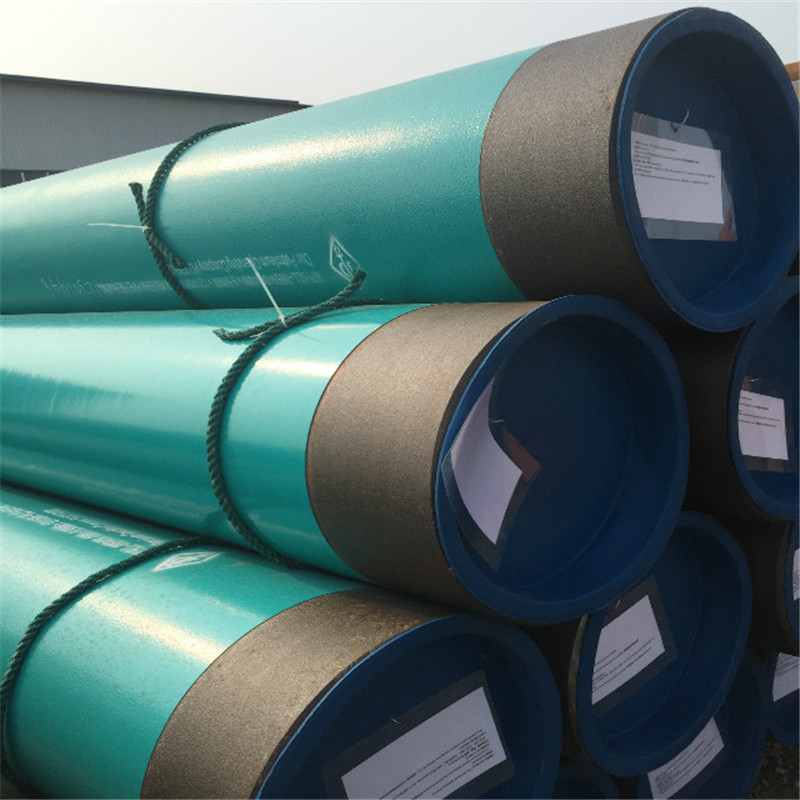

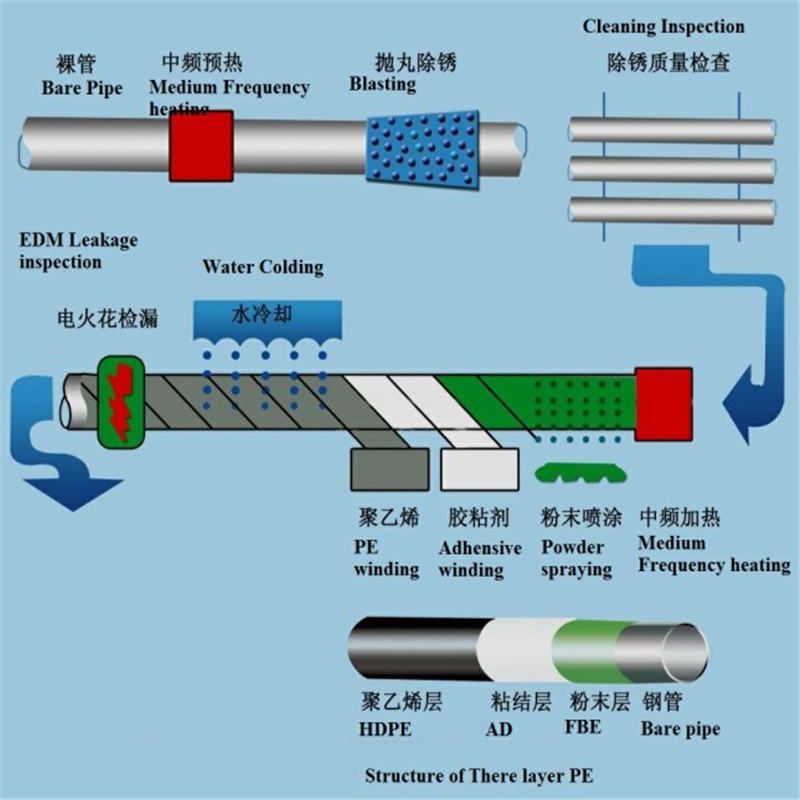

3PE Coatings

This type of coatings has many good factors, such as pipeline anti-corrosion and sealing is strong, as well as strong mechanical strength, good water resistance , stable quality, convenient construction, good applicability, and no pollution to the environment. PE also has low water absorption rate (less than 0.01%), high epoxy strength, low PE water absorption and good hot melt adhesive flexibility, etc. It has high corrosion resistance and reliability. The disadvantage is higher cost, compared with other joint material .

Cold-wrapped tapes as PF type and RPC type

cold-wrapped tapes as PF type and RPC type is easy on construction. The three adhesives matched make PF- cold-wrapped tapes available in construction under any environment, any season and any temperature conditions.

The characteristics of cold-wrapped tape and 3PE heat-shrinkable tape are: it is suitable for pipes of various materials, and other methods are suitable for pipes in the same or close to the material.

Process flow

Base surface treatment → paint allocation → brush intermediate paint → brush or spray construction → maintenance

Decho is a professional supplier of pipe with all kinds of anti corrosive coated pipes , including 3PE/3PP, FBE. Liquid epoxy , ect . If you need any for your project, pls feel free to contact us by email [email protected]