What should we pay attention to when using three screw pump?

What should we pay attention to when using three screw pump?

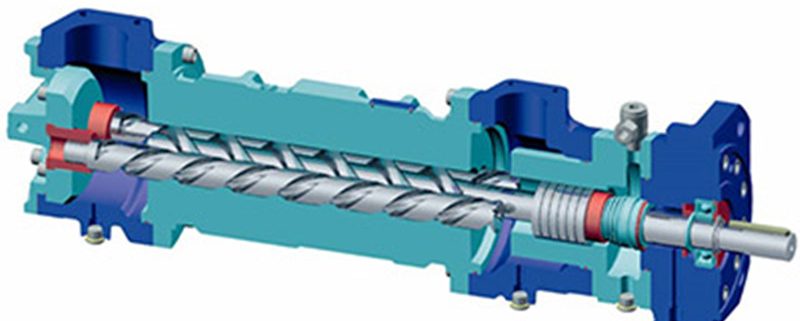

1. Selection of speed of three screw pump The flow rate of three screw pump has a linear relationship with rotation speed. Compared with the low-speed screw pump, the high-speed screw pump can increase the flow rate and lift, but the power is obviously increased. The high-speed screw pump accelerates the wear between rotor and stator, which will definitely lead to premature failure of the screw pump. Moreover, the stator and rotor of the high-speed screw pump are short in length and easy to wear, thus shortening the service life of the screw pump. The speed can be reduced by speed reducer or stepless speed regulation mechanism, so that the survey speed can be kept within a reasonable range below 300 revolutions per minute. Compared with the screw pump running at high speed, the service life can be prolonged several times.

2. The quality of screw pump There are many types of screw pumps in the market. Relatively speaking, the imported screw pumps are reasonable in design and excellent in material, but the price is high, some services are not in place, the price of accessories is high, and the ordering cycle is long, which may affect the normal operation of production. Most of the domestically produced products are imitations of imported products, and the quality of the products is mixed. When selecting domestically produced products and considering their cost performance, products with low speed, long lead, excellent transmission parts and long rated life are selected.

3. Ensure that sundries do not enter the pump body Solid impurities mixed in wet sludge will damage the rubber stator of screw pump, so it is very important to ensure that impurities do not enter the pump cavity. Many sewage plants have installed pulverizers in front of pumps, and some have installed grille devices or filters to prevent impurities from entering the screw pump. The grille should be cleaned in time to avoid blockage.

4. Maintain a constant outlet pressure Screw pump is a kind of positive displacement rotary pump. When the outlet end is blocked, the pressure will gradually increase to exceed the predetermined pressure value. At this time, the load of motor will increase sharply. The load of related parts of transmission machinery will also exceed the design value. In severe cases, the motor will burn out and the transmission parts will break. In order to avoid the damage of screw pump, a bypass overflow valve is usually installed at the outlet of three screw pump to stabilize the outlet pressure and keep the normal operation of the pump.

5. Avoid cutting materials Three screw pump will never be allowed to run under the condition of material breakage. Once it happens, the rubber stator will burn out due to the instantaneous high temperature caused by dry friction. Therefore, the crusher is in good condition and the grille is unblocked, which is one of the necessary conditions for the normal operation of screw pumps. For this reason, some screw pumps are also equipped with material breakage shutdown devices. When material breakage occurs, vacuum will be generated in the cavity due to its self-priming function, and the vacuum device will stop the screw pumps from running.

Decho is a professional supplier on screw pumps , if you have any request , pls donot hesitate to contact us by email [email protected] .