Two important factors that affect welding of steel and aluminum

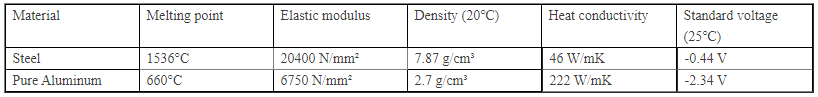

Steel and aluminum have different chemical and physical properties, such as melting point, thermal expansion coefficient, elastic modulus, etc. When welding steel and aluminum by hot working welding process, they will face many problems, that is, aluminum and steel are prone to form very hard and brittle IMP phases (Intermetallic phase), the greater the welding heat input, the more IMP phases are generated. This brittle stage severely destroys the static and dynamic strength of the joint and reduces the plasticity of the joint. Their main physical differences are as follows:

Steel can melt part of aluminum in a solid state, but when the aluminum content exceeds 12%, the crystal structure changes fundamentally, forming a very hard (250-520hv) and fragile mixture of FeAL (network) and Fe3Al (network). If the aluminum content in the mixture of Fe2Al , Fe2Al5 and FeAl3 is further increased, higher hardness (600-1100 HV) and higher brittleness are provided. This fragile material is the result of the diffusion of steel in aluminum or aluminum in steel. When the electrochemical potentials of two different materials are different, molecular diffusion occurs to compensate for the potential difference. The greater the potential difference (E~1.22v of steel and aluminum), the greater the diffusion tendency.

However, when the thickness of the IMP brittle phase of the welded joint is less than 10m, its brittleness becomes less important and obvious. At this time, the performance of the workpiece mainly depends on the ductility of the substrate. Corrosion is another major problem, because the electrochemical potential of these two materials is completely different, leading to electrolysis (equivalent to a battery), while the potential of aluminum is very low, and the negative electrode will corrode with electrolysis. In summary, the welding of steel and aluminum needs to meet two requirements:

- IMP phase thickness at the joint <10 m

- Prevent corrosion of base metal after welding

In order to meet these two requirements, a low heat input process is required, and then a special welding wire or weld seam anti-corrosion treatment is required.

CMT (Cold Metal Transfer) technology is developed on the basis of short-circuit transfer, and its heat input is much lower than ordinary GMAW welding. The process is: the arc burns, and the wire is pushed forward until the droplet is shortened. At this time, the wire feeding speed is reversed, the wire is pulled backward, and the current and voltage are almost zero. After the next loop is formed, the arc is reignited, and the droplet transfer begins again before the wire is reconnected. The average frequency of this feedback/pullback movement is as high as 70 Hz.

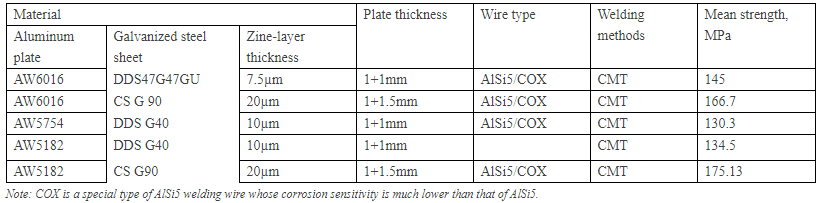

A successful example is based on the welding of galvanized steel and aluminum. The welding experiment is as follows: the thickness of aluminum is 0.83 mm, the filler is aluminum-silicon material, and the brazing seam is formed on the surface of the steel by melting aluminum and zinc. A 1 mm basic test was carried out at the junction of steel and aluminum. The following table is the average intensity of the test.

The strength loss of the heat-affected zone during the cold metal transfer process is inevitable. During welding and heat treatment of aluminum alloy, the strength of the heat-affected zone loses 30-40% due to the precipitation of crystals to form a mixed crystal structure. Therefore, the heat-affected zone of the joint is the weakest part of the joint, and the minimum tensile strength is about 60% of that of aluminum-based materials. For naturally hardened aluminum alloys, the strength of the heat-affected zone is also reduced due to re-crystallization. The strength reduction is related to the heat input during pre-treatment and welding, and the fracture mainly occurs in the heat-affected zone.

Test data show that welding of steel and aluminum is possible, but steel must be galvanized, and a special low-energy welding process is a prerequisite for success. Welded joints have good tensile strength, corrosion resistance and fatigue resistance, and the IMP brittle phase is less than 2.5m, which is the key to preventing brittle fracture of steel-aluminum joints.

Decho is a professional supplier of various aluminum , steel as well as aluminum alloy, steel alloy products and special treatment metal material and products, if you have such needs, please don’t hesitate to email [email protected] .