What are the commonly used pipeline anticorrosive coatings?

Classification of pipeline anticorrosion

Pipeline anti-corrosion is divided into pipeline main body anti-corrosion and patch weld anti-corrosion

How to choose pipe repair materials?

It depends on the material of the main pipeline anti-corrosion layer. Commonly used mending methods include petroleum asphalt mending, epoxy coal tar mending, adhesive tape mending, powder epoxy mending, and PE heat shrinkable material mending. If the main body of the pipeline is a three-layer PE composite structure, the first choice is the three-layer PE heat-shrinkable joint material. The patching of single-layer epoxy powder coating can adopt three methods: epoxy powder, adhesive tape + primer and three-layer PE heat shrink patching.

What are the commonly used pipeline anticorrosive coatings?

Epoxy anticorrosive coating

- Ring primer

- Iron red high anti-corrosion and anti-rust primer

- Zinc-rich epoxy anti-rust primer

- Zinc-rich epoxy anti-rust primer

- Cloud iron epoxy anti-rust primer

- Cloud iron epoxy anti-rust primer

- Hongdan epoxy antirust paint

- Iron red workshop primer

- Iron red epoxy deck paint

- Epoxy enamel

- Epoxy anticorrosive top coat

- Epoxy coal tar heavy anti-corrosion coating

- Epoxy coal pitch anti-rust primer

- Black antistatic and oil resistant primer

- Black antistatic and oil resistant finish

- Inorganic zinc silicate primer

Acrylic \ Polyurethane coating

- Polymer interpenetrating network anticorrosive primer

- Polymer interpenetrating network anticorrosive coating

- Gray aluminum powder graphite alkyd enamel

- Polyurethane anti-rust primer

- Polyurethane intermediate paint

- Polyurethane anticorrosive finish

- Acrylic polyurethane enamel

Chlorinated rubber anticorrosive coating

- Chlorosulfonated polyethylene topcoat

- Chlorosulfonated polyethylene primer

- High chlorinated polyethylene topcoat

- High chlorinated polyethylene primer

- Chlorinated rubber thick build deck paint

- Chlorinated rubber thick build anti-rust paint

- Chlorinated rubber ship hull paint

- Chlorinated rubber anticorrosive finish

- Chlorinated rubber waterline finish

- Perchlorovinyl varnish

- Perchloroethylene external enamel

- Perchlorovinyl primer

- Perchloroethylene anticorrosive paint

High temperature resistant anticorrosive coating

- Silicone heat-resistant primer

- Silicone heat-resistant enamel

- Silicone heat-resistant paint enamel

- Silicone heat-resistant paint

- Silicone heat-resistant paint

- Silicone heat-resistant paint

- Silicone heat-resistant paint

Anticorrosive coating for the inner and outer walls of oil tank

- Iron red epoxy modified polyurethane paint resistant

- Gray epoxy modified polyurethane paint resistant

- Epoxy polyurethane anticorrosive finish

Epoxy oil-resistant finish Interior and exterior wall architectural coatings

- Environmentally friendly interior wall paint

- Interior wall paint

- Exterior wall paint

- Elastic exterior wall paint

Special coating

- Reflective paint

- Fluorescent paint

- Gold paint

- Plastic paint

Cold galvanized Powder coating

- Powder coating

- Pure epoxy powder coating

- Epoxy polyester powder coating

Color steel plate waterproof coating

- Color steel plate waterproof coating

- Color steel plate waterproof coating

- Stitched polyester waterproof cloth

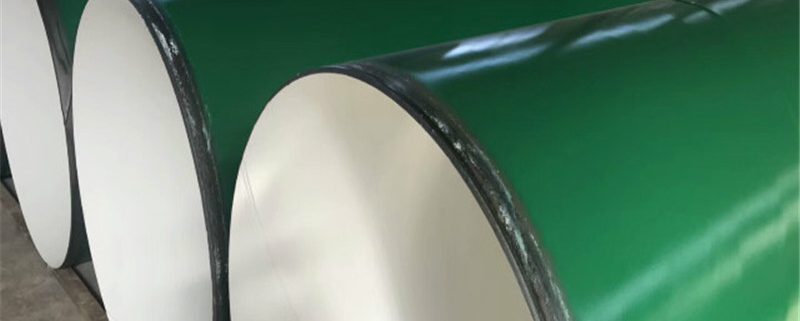

Decho is a professional supplier of steel pipes with anti corrosive coating . If you need any for your project , pls feel free to contact us by email [email protected]