what is cathodic protection?the methods to realize cathodic protection of underground pipelines and its technical requirement

Due to the long pipeline construction period, it is generally required if the soil resistivity is less than 20Q. m, it is necessary to install a magnesium anode for temporary protection and connect it to the pipeline through a test pile. When the impressed current cathodic protection is put into use, the temporary protection is removed. The Cathodic Protection is very important to protect pipes from corrosion .

what is cathodic protection?

It is a method of polarizing the protected metal into a cathode to prevent metal corrosion. This method has been used for ship anti-corrosion for more than 150 years; it was first used in pipelines in 1928, applying the principle that the cathode is not corroded but the anode is corroded in metal corrosion batteries to metal anti-corrosion technology. The externally applied current is used to force all the surface of the protected metal in the electrolyte to be catholic polarized, then corrosion will not occur. There are two indicators for judging whether a pipeline meets cathodic protection. One is the minimum protection potential, which is the potential of the metal in the electrolyte from cathodic polarization to the stop of the corrosion process; its value is related to environmental factors. The second is the maximum protection potential, which is the highest potential value that the metal surface to be protected can reach. When the cathodic polarization is too strong, hydrogen will evolve between the pipe surface and the coating, causing cathodic peeling of the coating. Therefore, the confluence point potential must be controlled within the allowable range to prevent the coating from being damaged.

Two methods to realize cathodic protection of underground pipelines

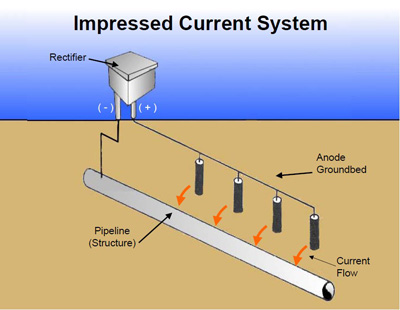

impressed current method

The impressed current method uses a DC power supply, with the negative pole connected to the protected pipeline and the positive pole connected to the anode bed. After the circuit is connected, the pipe is polarized cathode. When the pipeline’s ground potential reaches the minimum protection potential, complete cathodic protection is obtained. In order to determine the cathodic protection parameters and appraise the cathodic protection effect of the pipeline, it is necessary to set up inspection points and check sheets along the pipeline. The protection distance of a single station of impressed current cathodic protection is generally up to tens of kilometers, and this method is often used for cathodic protection of long-distance pipelines.

sacrificial anode method

The sacrificial anode method uses a metal with a more negative potential than the protected metal electrode to connect with the protected metal, and the two form a galvanic cell in the electrolyte. Metals with relatively negative potentials (such as magnesium, zinc, aluminum and their alloys) become anodes, which are gradually lost in the process of outputting current, and the protected pipe metal becomes cathodes to avoid corrosion. Therefore, metals with relatively negative potentials are called sacrifices anode.

Technical Requirement for applying cathodic protection .

To be economically reasonable and technically feasible on applying cathodic protection to the pipeline, certain conditions must be met, as follows:

①Ensure the conductivity of the longitudinal connection of the pipeline

②The covering layer of the pipeline must ensure sufficient resistance

③Ensure the electrical insulation between the pipeline and other low resistance grounding devices.

Decho is a professional supplier of 3lpe coated pipes , if you need any for your project , pls contact us by email [email protected]