What is a bimetal composite wear-resistant pipe?

What is a bimetal composite wear-resistant pipe?

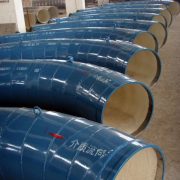

The outer wall of the bimetal composite wear-resistant pipe is made of ordinary seamless steel pipe, which is compounded by a high-chromium cast steel lining through a centrifugal forming process. The outer wall of the elbow is made of shrimp elbows, and the inner layer is made of high-chromium cast steel, which not only has the wear resistance of high-alloy cast steel, but also can withstand pressure, and has higher mechanical properties.

Bimetal wear-resistant pipeline characteristics:

1. Good wear resistance the hardness of super-hard wear-resistant alloy HRC≥46, with good wear resistance and thermal stability.

2. Excellent impact resistance, metal bonding performance, thermal shock resistance KMTBCr28 bimetal composite wear-resistant elbow, the bonding surface of the two metals is completely metallurgical, and it is safe and reliable to use. The thermal expansion coefficients of the two are equivalent, and there will be no expansion and contraction. The outer wall of the elbow is made of steel pipe, and the inner lining is made of super-hard wear-resistant alloy. This product not only has the wear-resistant and corrosion-resistant characteristics of high-alloy products, but also has higher mechanical properties and higher impact resistance.

3. Good heat resistance and corrosion resistance. The matrix of super hard alloy material has strong heat resistance and corrosion resistance, and can show good corrosion resistance and wear resistance under high temperature or corrosive environment. Under the interaction of wet state, corrosive media and particle erosion, it is more appropriate to use super-hard wear-resistant alloys used in as-cast state; and under dry conditions where abrasive wear is the main failure mode, use a A super-hard and wear-resistant alloy material that can obtain a martensite matrix through heat treatment.

4. Low composite cost and good quality The wear-resistant tube is manufactured using international advanced lost foam casting technology, with high yield, good product compactness, uniform thickness and stable quality.

5. Convenient transportation, installation and use The bimetal composite wear-resistant pipe can be connected by flange, quick joint, direct welding and other methods. Moreover, due to the high impact resistance of the composite pipe, when a partial blockage occurs during the maintenance of the pipeline system, it can be knocked, hammered, or cut, removed, welded, installed and repaired at will.

Decho is a professional supplier of bimetal composite wear-resistant pipe. If you need any for your project, pls contact us by email [email protected]