Three types of harsh environments requiring special bearings

Generally speaking, most bearings, cam followers and other rolling elements are made of AISI52100 material, which is a mixture of degassed low-alloy steel containing a large amount of chromium and carbon. AISI52100 material has high hardness grade and excellent wear resistance and deformability. These characteristics make AISI52100 material an ideal material for ball bearing and needle bearing applications. Bearings made of AISI52100 are used in a wide range of industries, from mining and material processing to entertainment and power generation.

However, standard AISI52100 bearings cannot withstand some harsh environments, so special materials are often needed to produce rolling parts. In these cases, AISI304, AISI440, AISI630, titanium, ceramic and grease-free bearings can be used.

When selecting the correct type of bearing material for your specific application, the following conditions should be kept in mind:

Corrosive environment

Many industries operate in well-known corrosive environments, including food processing, semiconductors, metal plating, medical equipment, and military markets.

In the food processing industry alone, high costs are required to repair corrosion-related damage every year. Food processing usually requires a lot of water, which is corrosive; high-acid foods, such as sauces, salad dressings and kimchi, are more corrosive. This environment can lead to rapid equipment degradation, costly maintenance downtime, and food contamination.

Equipment in the semiconductor and medical industries also undergo rigorous cleaning, decontamination and disinfection procedures, which usually involve the use of harsh corrosive chemicals. The metal plating process requires alkaline and acid treatments. The military has strict anti-corrosion requirements for equipment (including vehicles, weapons and other machinery) to help them withstand harsh environmental conditions.

For all these highly corrosive environments, standard AISI52100 bearings are unqualified; special corrosion-resistant bearings are required to ensure normal operation. In these cases, bearings made of titanium or AISI304, AISI440 or AISI630 stainless steel should be considered.

High temperature environment

The temperature in many industrial environments is at least 400 degrees Celsius (752 degrees Fahrenheit). For example, in the corrugated board manufacturing process, a series of rollers are used to curl the central groove and adhere the outer sheet to the groove. These rollers are heated to about 365 degrees Fahrenheit. To ensure normal operation, special high-temperature bearings are required. Metal processing also requires very high temperatures and corrosion resistance, because the pH value fluctuates during processing.

The ideal temperature-resistant bearing will be made of AISI304 or AISI630 stainless steel because these metals are resistant to both high temperature and corrosion. Grease-free bearings are another good choice because bearing lubrication often fails under high temperature conditions.

Electric environment

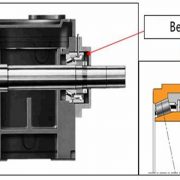

Electric current can cause incredible damage to metal parts. For the bearing, it will cause a series of problems, including the air passage in the bearing race, the pitting corrosion of the needle roller bearing and the decrease of lubrication performance. For example, various electric motors, electric traction motors in railway applications, and medical equipment such as magnetic resonance imagers all involve high-stress environments with large amounts of electrical activity.

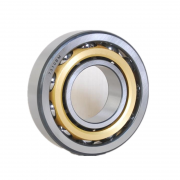

Ceramic bearings, as well as ceramic insulated metal bearings, are ideal for high-charge applications. Ceramic materials, with a few rare exceptions, are very poor electrical conductors; although they can accept large voltages, they can dissipate this electrical energy very effectively. The passing current hardly causes degradation.

Decho is a professional supplier of ceramic bearings. If you need any , pls contact us by email [email protected]